Organic Exhaust Gas Treatment

Technology Introduction

Organic waste gas is mainly derived from petroleum, chemical, paint, leather, printing and dyeing, paint and other industries in the production process emissions of waste gas, which is characterized by large amount of waste gas, frequent volatile organic , combustible and certain toxicity.

There are many methods of disposing exhaust gas at present, such as absorptive method, adsorption method, thermal combustion method, catalytic combustion method, plasma method and biological method. For the reason of different sources and types of organic gas, the componentof exhaust gas is different, therefore, disposing techniques are diverse.

This technology is used for disposing exhaust gas of leather industry.,mainly produced in spraying workshop. The component of organic gas are complex, large amount ,but concentration is low, mainly including acetone, isopropanol, n-butyl acetate, glycol ether, etc.

Depends on the composition and features of leather exhaust gas, physical absorption method is used to control the organic gas and the effect.is very good.

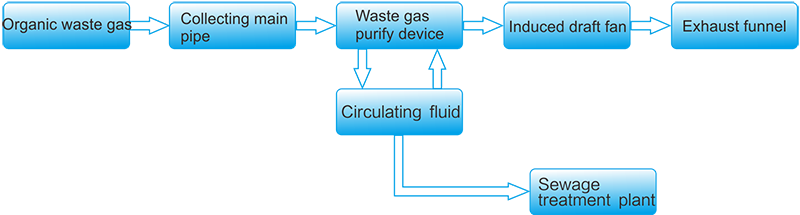

Process Flow Chart

Advantages

Compact equipment structure , elegant appearance and less invest;

Process is feasible, convenient operation management , and operating safely and steadily;

Flexible installation of equipment , maintance conveniently;

High processing efficiency and low. operating cost.

Application Case

One of Waste gas treatment project of a leather factory in Wenzhou, Zhejiang

Construction Time: 2010

Origin: leather workshop

Scale: 180000 m3/h

Standard: Intergrated emission standard of air pollutants (GB16297-1996)

One of Waste gas treatment project of a leather factory in Beihai, Guangxi

Construction Time: 2010

Origin: synthesis workshop

Scale: 120000 m3/h

Standard: Intergrated emission standard of air pollutants (GB16297-1996)